CNC firing is one of the types of automatic machining of metal elements. This is a method that is gaining more and more followers due to a number of advantages. This is one of the more accurate ways to cut metal elements.

What is CNC firing?

In short – it is a precise machining of various types of materials using a minicomputer located in a cutting machine. After designing the cutting model and entering the exact values in the computer, the machine cuts out the desired shape without human intervention.

The cut is incomparably more accurate than those made by man. Therefore, it is possible to perfectly repeat a given shape or pattern.

The main advantages include CNC firing:

- time saving;

- accuracy;

- repeatability;

- does not require special manual skills;

- increased efficiency.

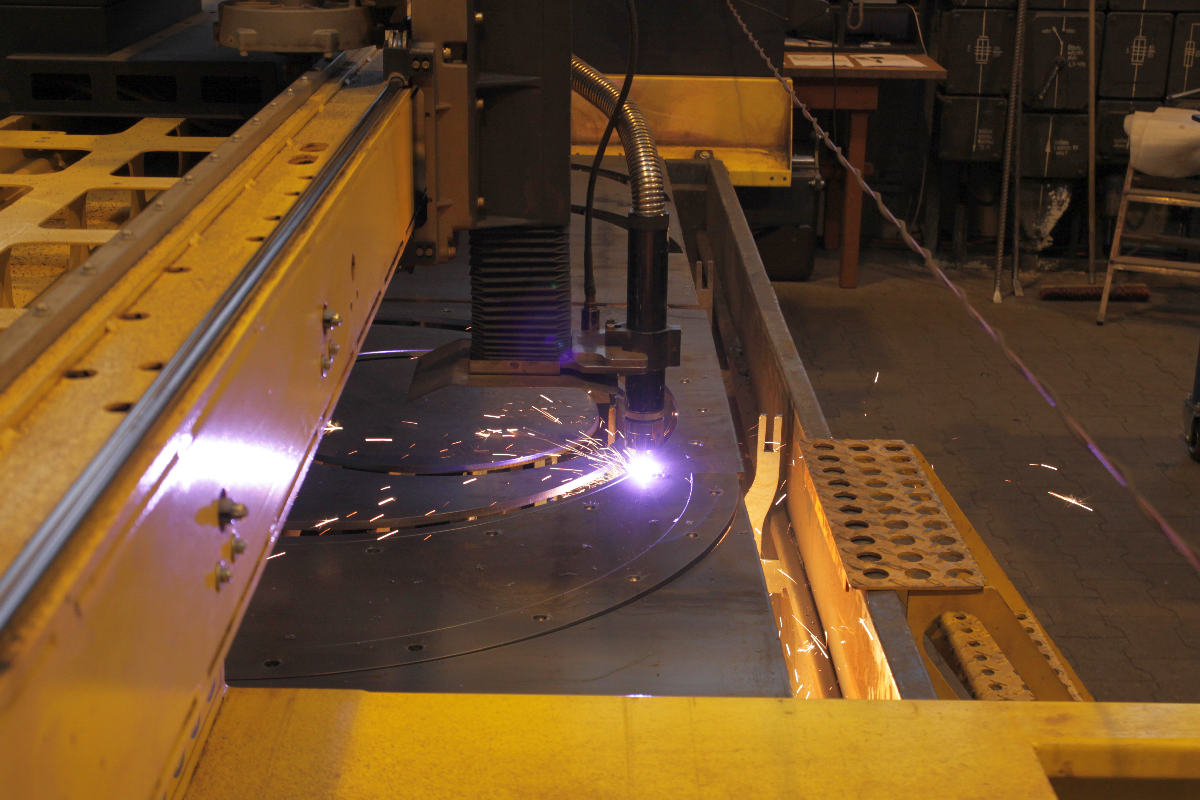

CNC plasma firing

Plasma is an oriented matter that resembles a gaseous form in its form. The resistance of the plasma decreases with increasing temperature, in addition, it is able to conduct electricity.

CNC plasma firing involves smelting metal with a highly concentrated plasma arc, which is characterized by relatively high kinetic energy. In other words, it is melting and throwing material out of the gap. This makes it possible to cut all materials that are good conductors of current.

Thanks to the rapid development of this technology, it is possible to cut thicker and thicker metals, more materials and significantly increase the speed of the process. This technology already existed in the 50s of the last century and is constantly being improved.

CNC firing – advantages

One of the most important advantages of cnc plasma firing cutting is its speed. Compared with another popular type of metal processing, which is oxygen cutting, the CNC firing speed is several times higher.

Despite the higher speed, cutting does not lose quality. The CNC plasma firing method does not heat the material and does not burn it. In addition, it does not damage its edges and contours. The original smoothness of the cut surfaces is also preserved.

The most important advantages of cutting with CNC plasma firing:

- negligible cutting gap;

- cutting without heating;

- high speed;

- high rate of production;

- no burning of thin materials;

- narrow zone of heat influence.

If you have more questions about CNC plasma firing – please contact us. Our specialists will answer all your questions.

CNC firing – gallery